examples of tpm|TPM Pillars—Eight Pillars of Total Productive : Tagatay TPM – Total Productive Maintenance Pillars. Developed in the early 50s, Total Productive Maintenance is a program for increasing efficiency of machines . 211 talking about this

examples of tpm,TPM – Total Productive Maintenance Pillars. Developed in the early 50s, Total Productive Maintenance is a program for increasing efficiency of machines .Nob 14, 2019 — The success of TPM program depends, among other things, on training and empowering maintenance team, using data and predictive analytics, and implementing proactive maintenance techniques into the maintenance .

Nob 21, 2023 — What is an example of total productive maintenance? TPM example involves Routine cleaning, lubrication, cleaning, and individual part replacement by machine .Dis 17, 2020 — Total Productive Maintenance (TPM) is a methodology applied to maintenance management, which focuses on: prevention (zero accidents, zero breakdowns, zero defects, .

This methodology emphasizes proactive and preventive maintenance, ensuring optimal equipment performance. By integrating TPM, organizations cultivate a shared responsibility .

In our detailed TPM guide, we explain the complex term and its history, explain the different building blocks of TPM, go into the advantages and disadvantages of the method using .

TPM Pillars—Eight Pillars of Total Productive In our detailed TPM guide, we explain the complex term and its history, explain the different building blocks of TPM, go into the advantages and disadvantages of the method using .

Real-World Examples of Successful TPM Implementation. Organisational Traits that differentiate Successful TPM Implementations. TPM Implementation Failures and Reasons – Learn from .May 19, 2020 — Planned maintenance. Early equipment/product management. Education & training. Quality management. Health, safety & environment (HSE) Administration & office. Find out more in our article, ‘So, what is TPM?’. Step .May 21, 2024 — Total productive maintenance (TPM) is a methodology designed to improve production systems by preventing problems. Its goal is to improve product quality, minimize .

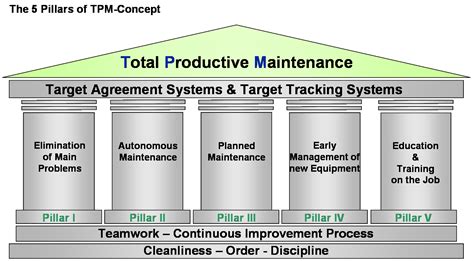

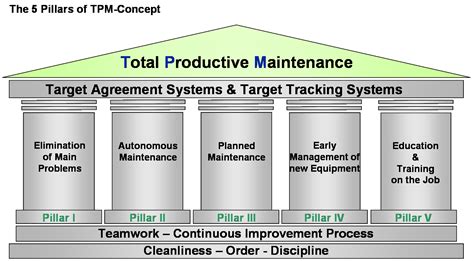

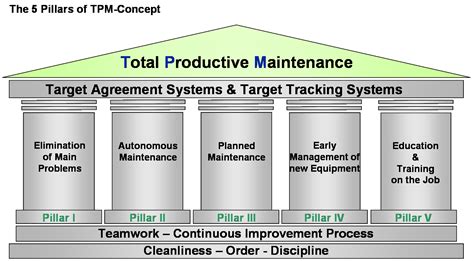

Peb 11, 2023 — Watch a Google TPM answer a mock interview question about data centers. Below, you’ll find several sample questions for each category. Practice just one type of question at a time. That way, you’ll get a better idea of your particular strengths and weaknesses. Read More: Check out our technical interview cheat sheet.examples of tpm TPM Pillars—Eight Pillars of Total Productive For example, if the workplace is clean and organized, tools used in maintenance are easily located – this has a positive effect on machine uptime. The Eight TPM Pillars Once a high degree of stability is established using the 5S program, an .Total Productive Maintenance Examples. One of the main tenets of TPM is introducing new everyday routines for everyone from upper management to plant personnel that are geared towards continuous process improvement. Following are some examples of these tasks. Machine operators do routine cleaning, greasing, lubrication, inspections, and .For example, TPM can help people determine whether all the meetings on the schedule are really necessary. What are the benefits of TPM? Going through every workday with no breakdowns, no defects, and no accidents is the dream. The benefits of the TPM model can bring organizations closer to that dream. 1. Fewer work stoppages due to unplanned .May 15, 2023 — Total Productive Maintenance, or TPM, is a lean maintenance strategy that aims for zero breakdowns, zero defects and zero work accidents. We’ve already introduced TPM, what it is, who is responsible for it, its numerous advantages, and how it fits into Industry 4.0.. However, to succeed at such an ambitious plan, we need solid pillars.That brings us to the 8 pillars of .Total productive maintenance (TPM) is the process of using machines, equipment, employees and supporting processes to maintain and improve the integrity of production and the quality of systems. What Is Total Productive Maintenance (TPM)? According to Aberdeen Research, the average hourly cost of downtime across all businesses is $260,000, and it seems to be rising.Ago 7, 2024 — A simple TPM attestation policy that can be used to verify minimal aspects of the boot. Sample policy for TPM using Policy version 1.2. The policy uses the TPM version to restrict attestation calls. The issuancerules looks at various properties measured during boot.examples of tpmHun 17, 2021 — TPM assigns the responsibilities for routine equipment maintenance tasks, such as lubrication, cleaning and inspection, to the regular operators of various machines throughout the facility. . For example, it wouldn't be unreasonable to take a reactive approach for equipment that is low-priority or has diminished breakdown risk. At the same .

May 21, 2024 — Examples of Total Productive Maintenance The TPM model. The TPM model starts with a set of company-wide principles called the 5-S Foundation. That foundation supports the eight pillars of TPM — distinct techniques designed to .One of the major goals of TPM and OEE programs is to reduce and/or eliminate what are called the Six Big Losses – the most common causes of equipment-based productivity loss in manufacturing. . Examples of common reasons for Equipment Failure include tooling failure, breakdowns, and unplanned maintenance. From the broader perspective of .

Case Studies of Successful TPM Implementation. TPM or Total Productive Maintenance is a maintenance strategy that aims to increase the efficiency and effectiveness of production by involving all employees. Many companies have successfully implemented TPM and achieved significant benefits. Here are 50 case studies of successful TPM implementation, compiled .

Mar 10, 2023 — An industry example of TPM . The company had implemented a focused 5S+1 program as the foundation for its goal of implementing TPM. Given the success of the 5S+1 program the VP of Manufacturing decided it was time .The TPM is the glue that holds these teams together. They keep a bird’s-eye view on what the teams are delivering and how the deliverables fit together. . Have examples that showcase your expertise and demonstrate how you’ve taken risks, succeeded, failed and grown. Make sure your answers are well-structured.Learn about the importance of Total Productive Maintenance (TPM) and find visuals or examples that you can use in your facility. Find guides, resources, and products that can help you start your TPM program today!Hul 8, 2024 — Total productive maintenance (TPM) is a maintenance management philosophy and strategy that maximizes production equipment effectiveness with the collective effort of all teams rather than just maintenance staff.. TPM engages employees at all levels—from floor plant technicians to senior facility managers—to boost production integrity, system quality, and .

These examples show how diverse industries implement TPM to maintain and improve equipment reliability and performance while also empowering employees to take proactive steps in maintenance processes. Continue reading: Total Productive Maintenance: Understanding Its Importance and Benefits. Read more

Okt 28, 2022 — Example technical questions asked in TPM interviews: Coding. Write a program that reverts a string (no built-in functions can be used) Write a program to find if an integer is a palindrome; Write a program to find common items between two linked lists;Real-World Examples of Successful TPM Implementation. There are many real-world examples of successful TPM implementation. These include companies such as Toyota, Coca-Cola, and Procter & Gamble. By studying these examples, you can learn from their successes and apply these learnings to your own TPM implementation. You can learn about 50 real .

examples of tpm|TPM Pillars—Eight Pillars of Total Productive

PH0 · What is Total Productive Maintenance (TPM)?

PH1 · What Is Total Productive Maintenance (TPM)

PH2 · Total Productive Maintenance [Ultimate Guide on TPM]

PH3 · Total Productive Maintenance (TPM): 8 Pillars, Benefits and

PH4 · Total Productive Maintenance

PH5 · The 7 steps to implement TPM into your organization

PH6 · TPM Pillars—Eight Pillars of Total Productive Maintenance

PH7 · TPM Pillars—Eight Pillars of Total Productive

PH8 · TPM Implementation: Best Practices, Learnings & Case Studies

PH9 · TPM Implementation: Best Practices, Learnings & Case Studies

PH10 · How to Implement a Total Productive Maintenance

PH11 · Guide: Total Productive Maintenance (TPM)